About us

About Us

In 2008, two leading players, Volvo Group and Eicher Motors, in the commercial vehicle business joined hands with a common vision of driving modernization in the commercial transport business in India. Volvo Group comes with global expertise, leadership in product technology, well-defined processes and a brand respected all over the world. Eicher Motors is a leader in the Light and Medium Duty Vehicle segment and brings to the table frugal engineering, considerable after sales infrastructure, and cost-effective operations. Together they complement each other and combine their strengths to deliver effective solutions that favorably impacts the eco-system. This partnership has helped modernise and evolve the industry in India and many other countries with emerging markets.

The company’s product portfolio includes the complete range of Eicher branded trucks and buses, exclusive distribution of Volvo Trucks in India, engine manufacturing and exports for Volvo Group, non-automotive engines and Eicher component business. A multi-brand, multi-division company, backed by innovative products & services, VECV today, is recognised as an industry leader in CV industry.

VECV offers a range of ultra-modern trucks across 4.9-55Tonnes, along with a wide range over 150 fully built and bus chassis variants across light, medium and heavy-duty applications.

The world of commercial vehicles is always on the move, be it new emerging markets, state-of-the-art infrastructure, new policies and the aspirations of customer. VECV is always ahead with a continuous transformation of a holistic ecosystem which is based on progressive thinking, advanced technology and unshakable values. This keeps VECV miles ahead from the rest.

WORLD CLASS MANUFACTURING

Bringing vehicles to life since 1986

VECV, one of the India’s leading manufacturers of trucks and buses, has always spearheaded the Future of Indian Trucking with the next-gen vehicles and innovative support solutions. Through every vehicle that we produce we help achieve people their dreams, ambitions and ensure they or their products reach their destination safely and on time. We understand the importance of trucks and buses, and how integral they are to keep the country running. Every day with relentless pursuit of perfection and exceptional quality, these vehicles are brought to life in state of the art VECV’s facilities.

PITHAMPUR PLANT

ETB completed 34 years of operations in India in the month of June 2020. The first Eicher truck was rolled out from its manufacturing plant in Pithampur, Madhya Pradesh in 1986 and over the past years, the products have got endorsement from hundreds of thousands happy customers. The plant is spread over 87 acres of land with current installed capacity of 90,000 vehicles per annum, producing over 1000 vehicles per acres.

- Highly flexible, lean, and agile environment delivering high quality trucks, Engines and bus Chassis

- Smart factory with right blend of automation, Produces 1000 vehicles per acres.

- Certified for Integrated Management System – encompassing Quality, Health & Safety, Environment and Energy Management system

- Volvo Production System as base for Manufacturing Operation

- The plant has a fully equipped vehicle and engine development center with fatigue lab, complete virtual vehicle integration capability and Simulation Lab

BAGGAD PLANT

To capitalize on the opportunity of improved road infrastructure and growth of smart cities, an ultra-modern bus body manufacturing facility was set up at Baggad (Madhya Pradesh) in September 2013. The plant is spread over a huge expanse 43 acres has a current installed capacity of 15,600 per annum, expandable to 19,200 per annum.

- The multi-model plant which manufactures Light, Medium and Heavy duty buses in Diesel, CNG & EV’s

- First of its kind bus plant which is equipped with high tech robotic paint system using wet on wet epoxy & PU painting from same robot.

- Certified for Integrated Management System – encompassing Quality, Health & Safety, Environment and Energy Management system

- Volvo Production System as base for Manufacturing Operation.

BHOPAL PLANT

To expand further and cater to dynamic market requirements and evolving customer needs, the Bhopal facility was initiated in November 2019. In less than a year, the assembly of first engine was rolled out in November 2019 from the new plant. The new facility will be utilized to manufacture VECV’s Pro2000 light duty BSVI range. Manufacturing plant in Bhopal spread over 147.8 acres of land and has an initial capacity of 40,000 trucks per annum, which would be scalable up to 100,000 per annum to align to future business plan volume requirements.

- Advance Powertrain & Vehicle assembly lines (BSVI compliant) with right blend of automation and frugal approach.

- Integrated Management System (IMS) and compliant to Industry 4.0.

- Lean and efficient material management from next door major ancillaries & Vendor managed warehouse.

- Green initiatives for sustainability – Zero discharge, Water conservation, Daylight & Rain water harvesting.

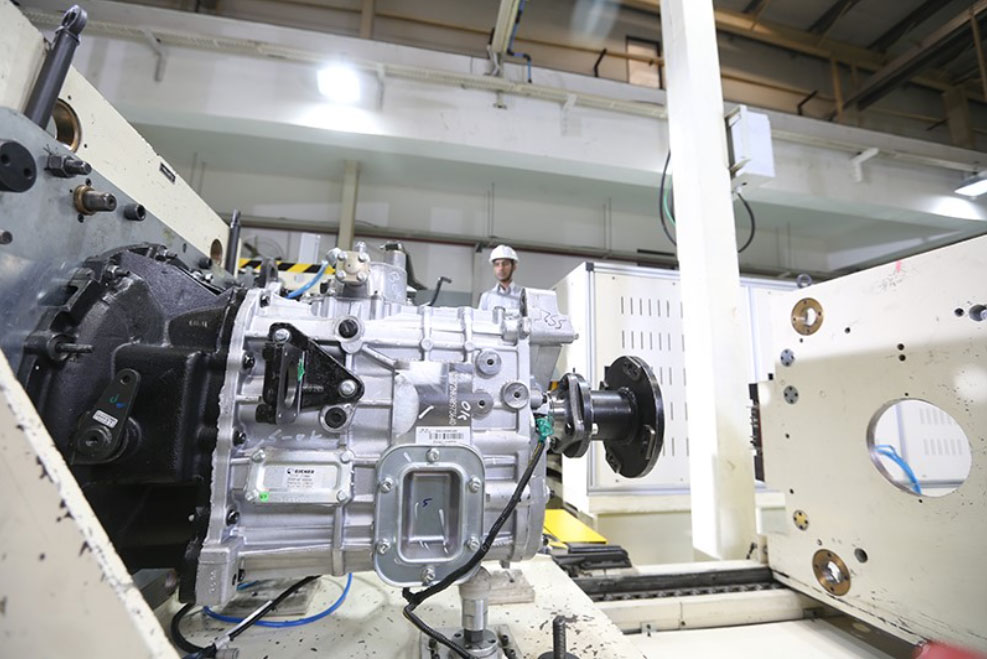

EICHER ENGINEERING COMPONENTS (EEC)

Eicher Engineering Components (EEC) is one leading Transmission, Aggregate and Component Business of VE Commercial Vehicles Limited. EEC came into existence in 1992 in a take-over of a Unit in Mumbai which was the first commercial gear manufacturing facility in India in the auto-ancillary sector. In the ensuing years, EEC has grown from strength to strength and is one of the leading Transmission, Engine and Axle components and aggregates manufacturers in India. EEC has customers across the globe and is strategic supplier to large OEMs like Volvo, Caterpillar, John Deere, Mahindra etc. besides meeting the captive requirements of Eicher Trucks and Royal Enfield.

DEWAS PLANT

Located in Central India in the industrial area of Dewas, Madhya Pradesh, India, the set-up is spread over approximately 30 acres, with another around 16 acres’ land available for future expansion. The state of art plant houses the latest technology in various processes for gear manufacturing, Crown wheel Pinion, Bevels and transmission assembly.

- Is one of the largest commercial gear manufacturing plants in India for Gear Grinding and Heat Treatment

- Has an exclusive New Product Development cell for expedited new product introductions

- Has an advanced and state-of-the-art Transmission Assembly line, running on MES (Manufacturing Engineering Systems)

- Certified to various systems for Quality & Environment Management and for Employees Health & Safety – IATF16949:2016, ISO 14001:2015, OHSAS 18001:2007

THANE PLANT

Located at the suburbs of Mumbai, Maharashtra, India, the plant has a total area of 6.5 acres. This plant is the first commercial gear manufacturing facility in India, with the plant setup in 1964, while Eicher took it over in 1992.

- Has a battery of Gleason machines for Spiral & Straight Bevels

- Has a variety of equipment for Heat Treatment & Gear Machining processes and for Inspection of Dimensions and Metallurgy

- Certified to Quality Systems Management under IATF16949:2016

SEZ PITHAMPUR PLANT

Located in the Special Economic Zone of Pithampur, Madhya Pradesh, India, the plant has a total area of 9.4 acres. The constructed area is around 1 acre with around 8 acres available for future expansion. The plant manufactures diverse variety of auxiliary gearboxes and aggregates for global customers

- Equipped with different assembly lines for light duty, medium duty and heavy duty aggregates, wet-on-wet painting facility and end-of-line testing and rig testing facilities

- Certified to various systems for Quality & Environment Management and for Employees Health & Safety – IATF16949:2016, ISO 14001:2015, OHSAS 18001:2007

NETWORK

At Eicher, we believe that the sale is just the beginning of the relationship and so it’s extremely important to partner the customer right through the life cycle of the vehicle. Therefore, Eicher has developed an extensive after-sales network that provides comprehensive support services.

The network of channel partners is fully equipped, trained & empowered to deliver best-in-class services, across all the highways & industry hubs in the country. The endeavor is to partner the channel to capitalize on the growth areas and opportunities in the CV industry, in not just vehicle sales but aftersales services, from genuine parts to site-support and resale too. The goal is to have a strong and fully engaged, efficient, customer centric, well-equipped and profitable dealer network, to achieve the status of ‘Customer Satisfaction No.1’.

Eicher Trucks and Buses Network

All channel partners are supported by dedicated and professional teams, which lay a firm foundation of sustainable business growth, understanding customer expectations and delivering a consistent experience.

The network channels comprises of:

- 3S Dealerships (Sales, Service and Spares) – 152

- 2S Dealerships (Service & Spares) – 164

- SPD(Spare parts distributor) - 27

- EGP (Eicher Genuine Parts Shoppe) - 100

- MBR(Multibrand Retailers ) – 2823

BRAND STORY

At Eicher we believe:

It’s never about me. But about we

Never about mine. But about ours.

It’s never about just one company but about an entire nation.

Because more than working hard. Or working smart.

We believe it’s more about working together.

Working together to set new professional standards

And with the world’s best to give you next-gen productivity vehicles.

Then working with drivers, mechanics and the support network

to keep our promise of ensuring your vehicle is on-road always.

We work with you at every step of the journey,

to ensure the profitability of your business.

Because we believe, when you get a vehicle from us, you become a part of our community and together we are

PARTNERING PROSPERITY